Data Contextualization for Advanced Reporting & AI Applications

In the digital age, data is often referred to as the new oil. However, like crude oil, raw data is...

Launching a new product, or New Product Introduction (NPI), is a high-stakes journey, fraught with financial and operational uncertainties. Amplifying these risks are the ever-evolving complexities in today's product systems, evident in industries like automotive and medical technology.

This blog post unpacks these challenges and presents strategic solutions to ensure a smoother and more successful product launch.

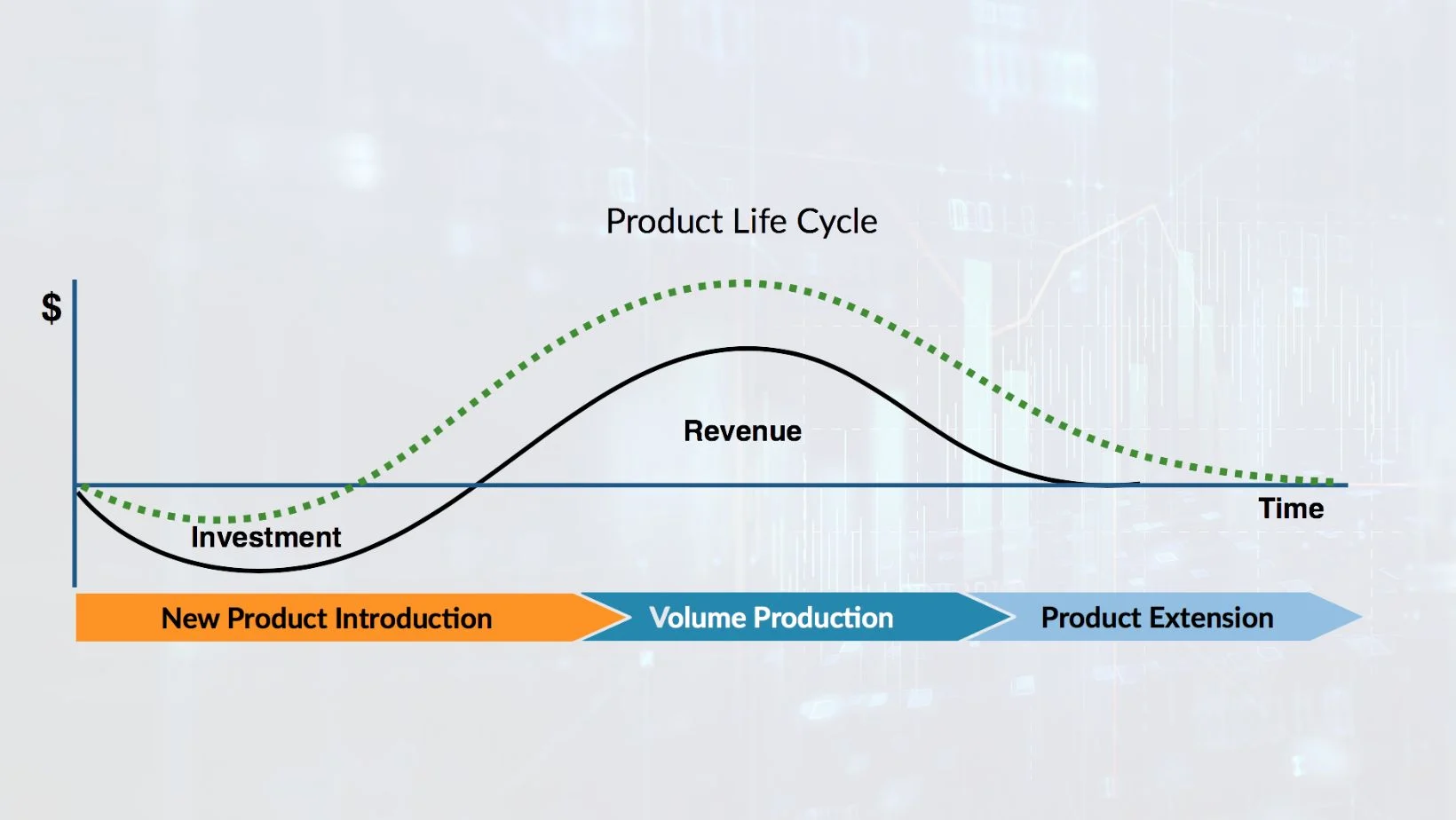

New Product Introduction (NPI) is the highest risk portion of your product life cycle. Investment cannot be recouped until the product is able to be manufactured in volume, yielding at the right level of performance, reliability and cost.

Exacerbating this risk is the growing complexity and integration of electronics systems in today’s products

In the automotive sector, for example, enhanced reliance on electronic features is giving rise to reliability issues, demanding greater attention to quality assurance throughout the NPI process. Similarly, the medical device sector's increasing use of integrated semiconductor technologies is pushing the risk envelope. Here, field failures can lead not only to exorbitant costs but can also result in catastrophic outcomes.

The integration of Enterprise Resource Planning (ERP) systems and Manufacturing Execution Systems (MES) can be a powerful ally in mitigating NPI risks. Together, these systems can streamline product tracking down to the unit level, a critical requirement for addressing three of the main categories of NPI manufacturing risks:

Line Failures: These are typically due to assembly issues, testing irregularities, supplier reliability, or product manufacturability problems.

On-time Delivery Failures: These can arise from inefficient manual data collection and tracking procedures, or lack of visibility into product assembly cycle times.

Field Failures: These usually stem from poor product reliability or subpar product performance.

Despite the benefits that ERP and MES integration can offer, a key problem persists: many factories still operate their systems as isolated units. These systems are often disconnected from the broader IT infrastructure, inhibiting their ability to capture and store the necessary data for comprehensive product traceability.

Furthermore, the prevalent use of spreadsheets and paper for production floor operations adds a burdensome, time-consuming layer of manual labor. This approach restricts the capacity to scale and automate data collection and inadvertently inflates engineering costs and time to market.

The solution lies in prompting assembly and test system vendors to open their software for broader data collection and integration with backend databases. Data collection must not only be meaningful and relevant but also easily portable. In an era where data is a goldmine, locking it up on an assembly system is counterproductive. Additional license fees are an unnecessary expense, especially when access to the data via other means remains elusive.

In conclusion, navigating the treacherous terrain of NPI demands a thorough understanding of the various risk factors, a comprehensive approach to data management, and an unwavering commitment to system integration. Through these strategies, it is possible to reduce the risks associated with NPI and ensure a smoother, more successful product launch.

3 Things To Think About When Choosing Between an ERP or MES System - If you are trying to decide between an MES or ERP solution, you will want to provide answers to the following questions before making your final choice.

Silicon Photonics: A Complex Supply Chain Requiring High Levels of Traceability - In this blog post, we will explore how traceability helps ensure the quality of silicon photonics products.

Eliminate Manual Data Collection in Manufacturing - Many manufacturers, realizing the inefficiencies of paper, are making steps toward digitization. Learn with us what you need to evaluate when going digital.

Traceability for Surface Mount Technology (SMT) Process - Enhance SMT efficiency and quality with traceability. Learn how barcode scanners, data logging, MES, standardization, and training drive success

In the digital age, data is often referred to as the new oil. However, like crude oil, raw data is...

Manufacturing Execution Systems (MES) are highly powerful automated systems deployed in...

In the vast realm of manufacturing, perfection at the first go isn't always a given. The process...