Serialized Traceability is Driving Real Change

Serialized traceability – the next phase of evolution for “track and trace” – is revolutionizing...

Serialized traceability is a process that assigns unique identification codes to products and parts as they move through the manufacturing and supply chain.

These codes are used to track the products and identify any issues that may occur. By tracking products and parts from creation to delivery, serialized traceability can help companies reduce waste, improve quality, and prevent recalls.

In this post, we will explore everything you need to know about serialized traceability. Let's get started!

Serialized traceability is the process and/or technology of tracking serialized items throughout the supply chain from manufacture to sale. This can include product identification, labeling, packaging, and track, and trace systems.

Serialization involves assigning a unique identifier to each unit of a product so that it can be tracked as it moves through the supply chain. This identifier can be a barcode, RFID tag, or other types of unique identifier.

Serialized unit traceability provides for complete genealogy, including material and component supplier source information, product testing, and QA results.

The term "Industry 4.0" is becoming more popular, although the meaning remains vague. What exactly does it imply? How might it benefit my business?

The essence of Industry 4.0 is to collect as much data as possible: transactional data, parametric measurements, statistical information, and all other manufacturing floor data. Then that information is put to good use.

From initial trial runs through volume production; from assembly to test to final shipment, each process step is analyzed in terms of its effect on overall performance and quality.

When that data is captured for each individual part on a line, that’s called serialized traceability. Serialized traceability is what underpins this next phase in the evolution of “track and trace." It’s changing how businesses leverage Manufacturing Execution Systems (MES).

Serialized traceability can provide many benefits throughout the supply chain, including:

In highly regulated industries such as aerospace or medical, the ability to isolate products down to the lot or batch level is a requirement. This level of traceability helps narrow the search quickly when the hint of a quality problem or product recall looms.

Quality and efficiency improvements that come from going one level deeper using serialized traceability, drive change on a transformational level. Clarity emerges on the role of every supplier, procedure, machine, and the person that raw materials have encountered along the way to becoming a finished product. Areas of focus for efficiency and cost-cutting improvements become obvious.

The combination of automated data collection and accessible, intuitive analysis tools gives everyone in the organization the power to drive continuous improvement.

With today’s mix of on-premise and cloud-stacking technologies, operators, engineers, plant floor supervisors, production planners, accounting and senior management can all examine every process in the production trail using their mobile phones, tablets or desktop computers.

Intraratio takes serialized traceability to the next level, with integrated product yield and performance data.

This rich set of data provides unparalleled ability to correlate production yield against all factory-induced variables.

Examples include:

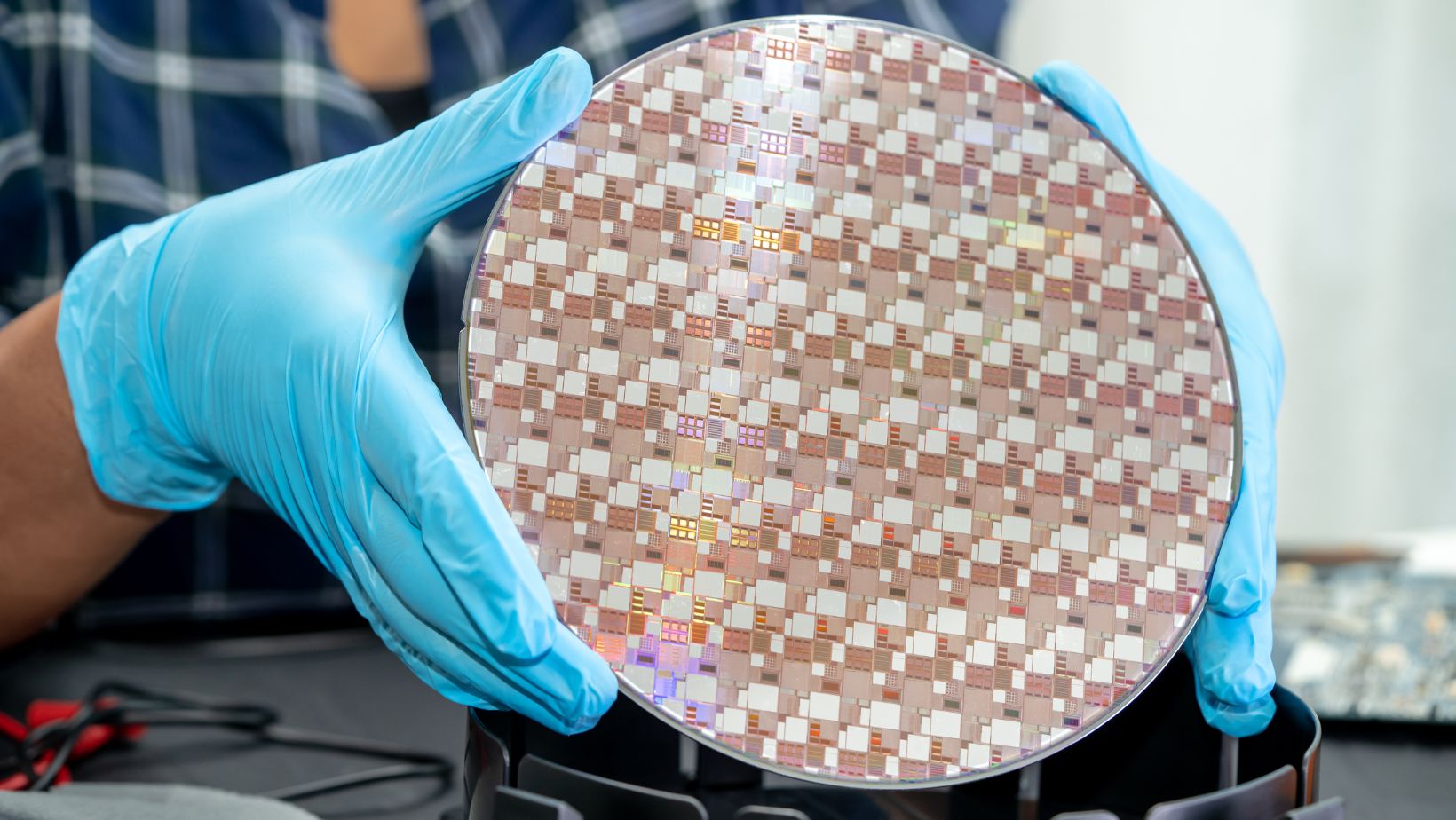

Deep traceability has been successfully achieved for products used in space and military communications systems currently in orbit, to advanced medical diagnostic systems using silicon photonics.

RunCard MES incorporates true serialized traceability into your production line. Implementations can be as short as a few weeks. Learn more about the exciting new era of Industry 4.0 by contacting Intraratio, a provider of an MES solution on the leading edge of technology.

What is Industrial AI and Why Does It Matter to Process Manufacturers? - Lets take a closer look at what you need to know about Industrial AI, including industry 4.0, IoT, machine integration, and automated traceability.

Serialized traceability – the next phase of evolution for “track and trace” – is revolutionizing...

Industrial AI, also known as AI in Manufacturing, is the use of artificial intelligence...

Silicon Photonics has been identified by the global market research firm IDTechEx as one of the...